Bespoke furniture manufacturing is the process of designing and building furniture to fit a specific space, programme and set of constraints, rather than adapting a standard product to suit after the fact. In commercial environments, this distinction matters most when spaces are awkward, constrained or non-standard.

In short: bespoke furniture is specified, built and installed around real constraints, rather than relying on on-site adjustment to make standard products work.

This guide is written for people responsible for getting commercial spaces operational on time. The ones dealing with programmes, budgets, access constraints and live environments.

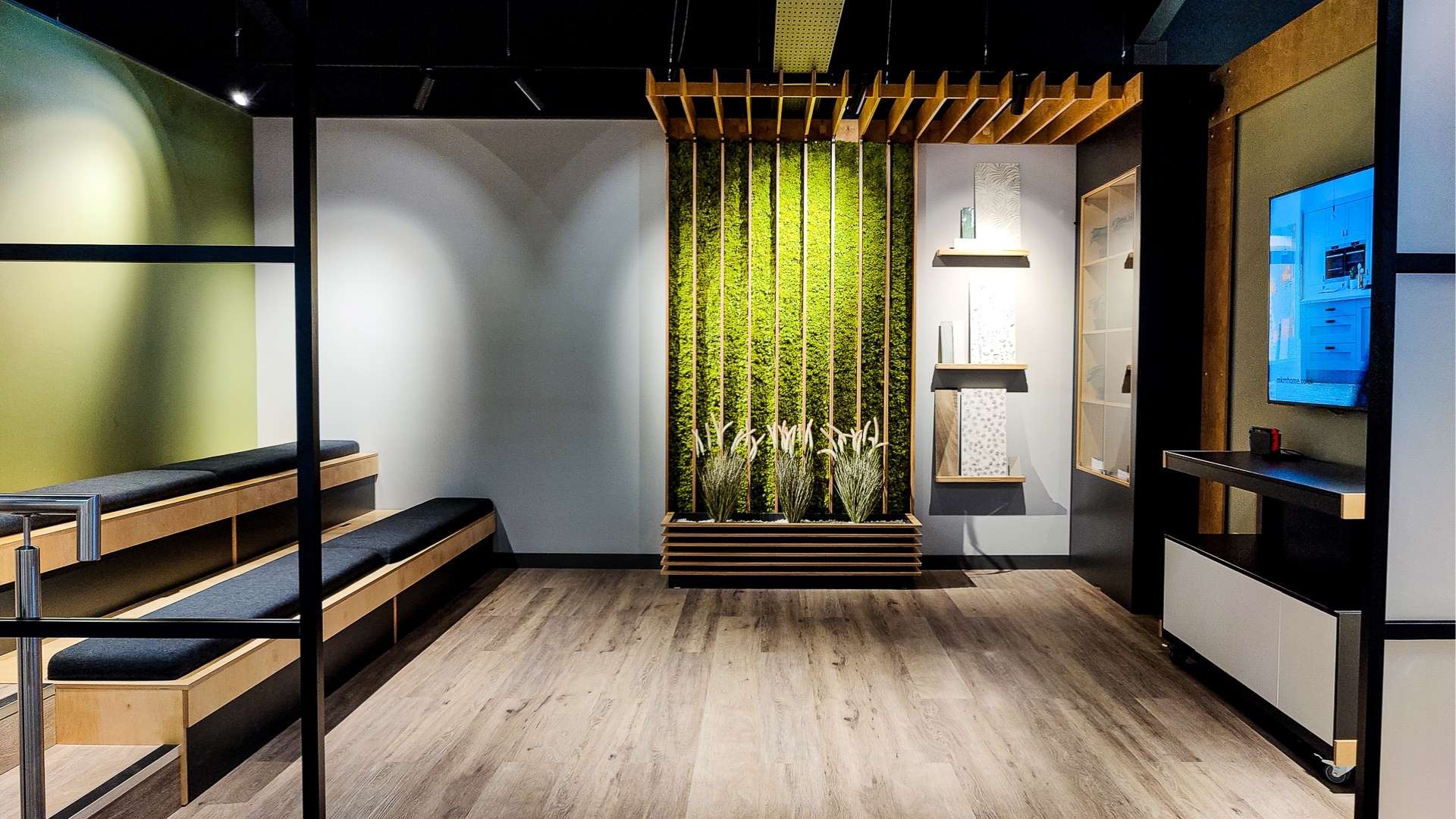

Whenever you are setting up a shop, you’ll need to understand how bespoke furniture is specified and manufactured to get your business ready for opening day as smoothly as possible.

When bespoke furniture is misunderstood at this stage, issues tend to surface later down the line. These obstacles delay manufacture and interrupt work on site, or during installation. These are times where they are hardest to fix, so the aim here is not to showcase design ideas, but to explain how bespoke furniture manufacturing actually works, and where early decisions protect delivery.

RED is outlining the essentials of the commercial fit-out process to give you a clear oversight of what they are, why they matter, and how to handle complex retail spaces without headaches.

We focus on how specification, manufacturing and installation decisions work together in practice. Not design theory or inspiration, but the practical steps that reduce compromise, protect quality and help complex spaces open as planned.

Why awkward spaces break standard furniture

Many commercial interiors fall somewhere between two conditions: spaces that are broadly regular, and spaces shaped by constraints.

Those constraints might include irregular walls, structural intrusions, legacy services, restricted access routes or the need to work around live operations. None of this is unusual in commercial buildings, and if you’re working with older estates or adapted properties, you’ve likely already identified these particular concerns.

Where these constraints exist, standard furniture starts to rely on compromise and more precise planning is required to maximise their performance.

These awkward gaps are typically filled on site and components are cut back to fit, or layouts are adjusted late to avoid clashes. These fixes rarely show up in drawings, and while quick adaptations can be an adequate solution to keeping the project moving forward, durability, finish quality and installation time are often compromised.

This is where planning decisions start to matter. When constraints are not resolved early, they are pushed to site, where installers are forced to adapt standard products in real time. That might keep work moving, but it transfers risk into installation where tolerances are tighter and options are limited.

Bespoke furniture manufacturing addresses this earlier in the process. Instead of correcting fit on site, dimensions, construction methods and allowances are resolved before manufacture begins. That does not remove complexity, but it allows compromises to be understood, agreed and controlled, rather than introduced under pressure during installation.

Where standard furniture starts to fail in awkward spaces

Standard commercial furniture is designed around repeatable dimensions, predictable layouts and clear access. These assumptions hold in regular spaces, but they begin to break down when applied to constrained or irregular floorplans.

One of the first pressure points is geometry.

Standard units assume uniform dimensions. Small deviations in walls or floor levels can quickly result in gaps, uneven reveals or misaligned doors and drawers. On site, these issues are often addressed through scribing, packing or cosmetic trims. While effective in the short term, these adjustments add labour and introduce weak points into the finished installation.

Services create another common clash.

In live environments, power, data, heating and ventilation routes are not always documented accurately. Once standard furniture is manufactured, flexibility is limited. Installers are left to cut apertures on site or reroute services around fixed components, neither of which supports clean installation or predictable programmes.

Access and operational constraints expose further limitations.

Large pre-built units may not fit through doors, lifts or stairwells. Furniture that has not been designed with installation sequencing in mind struggles to accommodate phased working, regulatory requirements or restricted access, often resulting in delays and unnecessary disruption.

In practice, these compromises accumulate. Individually they may appear manageable, but collectively they affect durability, cleanability, accessibility and long-term maintenance. Bespoke furniture manufacturing addresses these issues upstream, by resolving fit, construction and sequencing before installation, rather than correcting problems on site.

From brief to specification

Most installation problems originate in the brief, not the factory.

When these problems aren’t addressed until installation, the solutions to these problems are typically makeshift and have to be made around site constrictions, leaving you with a ‘make-do’ end product.

Approach these concerns at the design phase. This means creating a plan that focuses on dimensions, tolerances and access constraints being built into the furniture before they arrive to site, allowing manufacturing and installation to follow a controlled path.

The most important phase in bespoke furniture manufacturing happens before anything is cut.

A workable brief outlines the appearance while also capturing dimensions, tolerances, usage patterns, cleaning regimes, access constraints, installation sequencing and sector-specific requirements. It’s an exhaustive list, but in awkward spaces, this information is crucial and can be gathered through site surveys rather than relying on blueprints alone.

Measured surveys confirm wall conditions, floor levels, service locations and fixing zones. They also identify constraints that affect manufacture, such as maximum component sizes dictated by access routes or lift capacities.

A professional finish takes these details to inform how furniture is broken down, labelled and assembled later.

Turning site information into a buildable specification

Technical drawings and specifications are developed from survey data to agree tolerances and build them into the project.

Furniture is rarely built to “tight fit” everywhere; controlled allowances are designed in to accommodate building movement, irregular substrates or future maintenance access. Making these decisions explicitly, and in line with an awkward space, protects both manufacturing accuracy and installation outcomes.

Material specifications are also finalised at this stage. Board thicknesses, edge details, finishes and fixing methods are chosen based on durability, compliance and expected use, not just aesthetics. In regulated environments, fire performance, cleanability and accessibility requirements influence construction details early on.

Approval stages matter. Signed drawings and specifications lock down dimensions and interfaces, reducing ambiguity once manufacturing begins. Changes after this point are possible, but any solutions that can affect the programme manage timelines and costs in predictable ways.

A clear brief-to-specification process turns bespoke furniture from a perceived risk into a controlled exercise. Accuracy here reduces rework, prevents site-based improvisation and ensures that what is manufactured can be installed as planned.

Manufacturing methods and materials

Manufacturing methods determine how accurately furniture can be built, handled and installed without on-site adjustment. Throughout the process, these methods and decisions are made with installation in mind.

Component sizes, weight and handling requirements influence how furniture is packed, labelled and delivered. This work is conducted to align with the aim of arriving on site with furniture that fits, assembles cleanly and performs as intended without modification.

The choice of manufacturing method is shaped by project volume, complexity and performance requirements…

CNC machining and dimensional accuracy

CNC machining is central to accuracy and repeatability in bespoke furniture manufacturing.

Ideal for awkward spaces, CNC allows panels, components and apertures to be cut consistently to specification, which is critical when furniture interfaces closely with walls, services or adjacent elements. These processes also support batch consistency for multi-site projects, even where dimensions vary slightly between locations.

Joinery and structural assembly

Material choice directly affects service life.

Commercial furniture typically prioritises durable boards, laminates and finishes that withstand cleaning regimes and impact. Water-based paints, wipe-clean surfaces and radius edges are selected for both performance and maintenance considerations.

Controlled finishing and consistency

Finishing processes are controlled in-house where possible and form the final stage of manufacture. Consistent application of paints, laminates or coatings reduces variation between components and allows finishes to be matched accurately for future additions or replacements.

Quality control and consistency

Quality issues are easier to resolve in the factory than on site, and quality control must extend beyond a single inspection at the end of production.

A structured quality control process prevents variation from being built into furniture and ensures issues are resolved before installation, where time, access and options are limited.

Quality control is an integral part of production and exists to prevent reactive fixes during installation.

Initial checks confirm that materials match the approved specification. Board types, finishes and fixings are verified before machining begins. During production, dimensional checks ensure components meet tolerance requirements, particularly where interfaces are critical.

Embedding checks throughout the manufacturing process helps maintain control over programme and cost. Assembly stages include fit and function checks, with doors, drawers and moving parts tested for alignment and operation. Where furniture is modular or repeatable, standardised processes are used to maintain consistency across batches and sites.

Documentation supports quality as much as inspection. Component labelling, drawings and fixing schedules reduce ambiguity during installation, particularly in awkward retail spaces. These records also provide a reference point for future maintenance, repairs or replacement components.

Before dispatch, furniture is reviewed against the approved specification and installation plan. Any deviations are identified and resolved in the factory, where corrections are faster and less disruptive than on site.

This approach reduces snagging, shortens installation time and protects programme certainty. For estates and procurement teams, it also creates a clear audit trail, demonstrating how quality has been managed deliberately rather than assumed.

Compliance and performance requirements

Performance requirements for commercial furniture directly influence how it is designed, specified and built. Compliance is not a parallel process; it shapes material selection, construction methods and detailing from the outset, particularly in regulated or high-use environments.

Fire performance is a fundamental consideration. During planning, boards, laminates, adhesives and construction methods are selected to meet the UK Furniture and Furnishings (Fire Safety) Regulations. Fire-rated materials and documented test data are specified early to avoid substitutions later in the programme, where options are more limited and compromises more likely.

Durability requirements are equally influential. Furniture in education, healthcare and public buildings is subject to frequent cleaning, impact and movement. Without appropriate construction details, edge treatments and fixings, wear appears quickly and service life is reduced. Designing for durability at the manufacturing stage allows furniture to withstand these conditions without reliance on later reinforcement or repair.

Accessibility requirements affect furniture dimensions and layout. Reach ranges, clearances, heights and handle design must be resolved during specification, as they influence carcass construction and fixing positions. Addressing these requirements early ensures furniture can be used safely and comfortably by all users, without adjustments on site.

Site-specific and sector-specific constraints add further layers. Healthcare environments require wipe-clean surfaces and infection control considerations. Education projects often demand robustness alongside restricted installation windows. Public sector work may introduce framework requirements and documentation obligations that influence both specification and programme.

Compliance must shape manufacturing from the outset. It cannot be added at the end of installation or worked in with ad-hoc site changes.

Fire performance, durability and user requirements influence materials, construction and detailing. When these factors are resolved early, bespoke furniture performs as intended throughout its service life and remains maintainable as needs change.

Installation in real environments

Installation is where manufacturing decisions are tested against reality.

When manufacturing and installation are aligned, bespoke furniture arrives ready to fit, installs quietly and performs as specified for minimal disruption and dependable performance from day one.

In constrained or live environments, installation planning is as important as fabrication. Access routes, delivery timing and sequencing must be agreed in advance to avoid disruption to building users.

Furniture may be delivered in phases, pre-assembled where access allows, or deliberately broken down to suit lifts, stairwells or restricted working areas. These decisions affect how cleanly furniture can be installed and have a direct impact on programme progression.

Clear labelling and documentation support controlled installation. Components are identified by room, elevation or location, with fixings and instructions aligned to the installation plan. This reduces on-site interpretation and limits judgement calls under pressure, particularly where work must be completed out of hours or around live operations.

Manufacturing choices directly influence installation outcomes. Furniture designed with tolerance allowances, replaceable elements and planned service access installs more predictably and remains maintainable over time.

By contrast, furniture that relies on on-site cutting or adjustment increases dust, noise and variability, and often introduces avoidable delays.

Sequencing also plays a critical role, particularly in healthcare, education and public buildings. Installation may need to align with infection control measures, safeguarding requirements or phased handovers. Furniture designed with these constraints in mind supports controlled delivery rather than forcing last-minute changes.

Bespoke furniture as a controlled manufacturing process

Bespoke furniture manufacturing exists to address conditions that standard products are not designed to handle.

In awkward or constrained spaces, success depends on controlled processes, accurate information and practical experience, rather than visual impact alone.

When bespoke furniture is treated as a manufacturing exercise rather than a design add-on, it reduces risk rather than introducing it. Clear briefs, measured surveys and defined tolerances establish control early. Material choices, manufacturing methods and quality checks protect performance. Installation planning ensures that complex environments can be delivered without disruption or compromise.

This guide has focused on how bespoke furniture is specified, made and installed in real commercial settings. It reflects an approach where furniture is built to suit the space, the programme and the conditions in which it will be used, with decisions carried consistently from brief through to installation.

Related manufacturing guides

If you’re looking to explore related topics, you can find more information in our articles to understand how to manage awkward office layouts, fire-rated commercial furniture and how bespoke manufacture integrates with wider fit-out programmes.

Explore related manufacturing guides or view how bespoke furniture integrates into commercial fit-out planning.