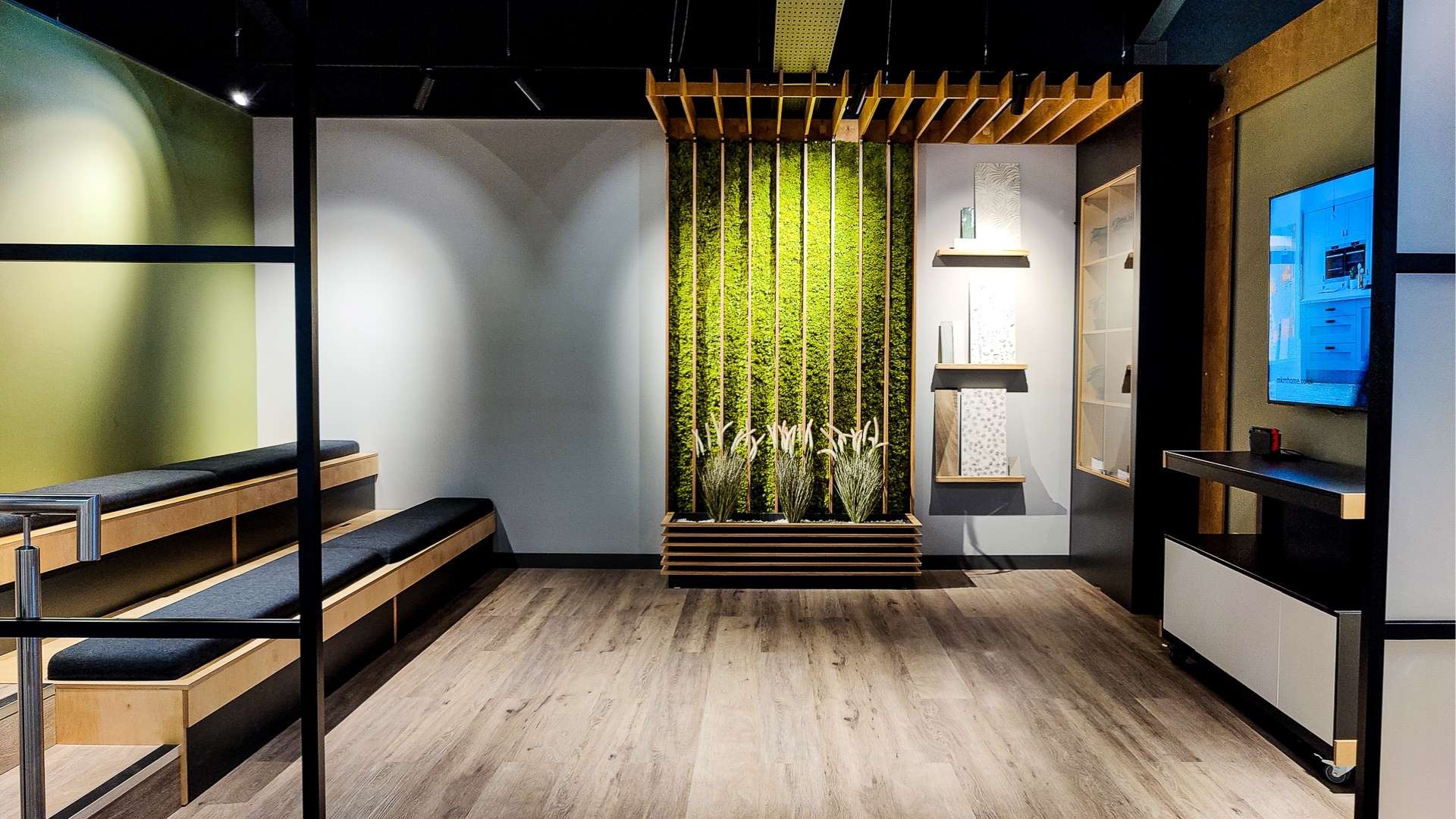

AkzoNobel required a high-tech customer centre within the head office. The space needed to present brands, sample colours and preview product innovation. The footprint was 6,400 sq ft.

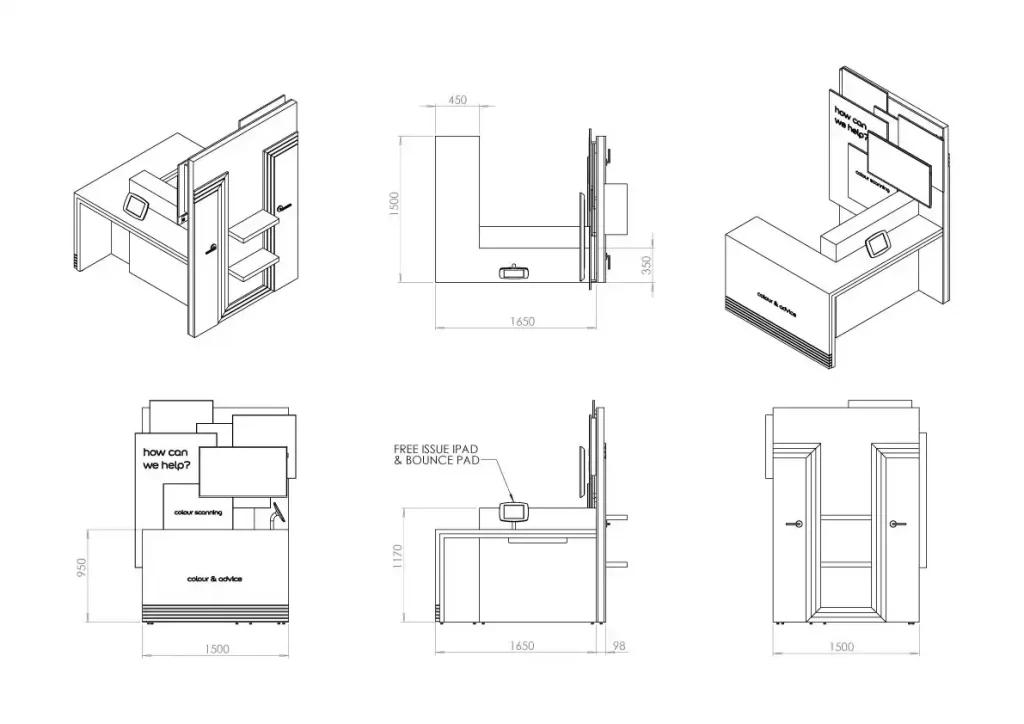

V2 Studios provided the concept. RED’s role was to interpret the scheme into manufacturable specifications and deliver full manufacture and installation in Slough.

We ran technical design for manufacturing in-house. We translated V2’s drawings into production models and issue packs.

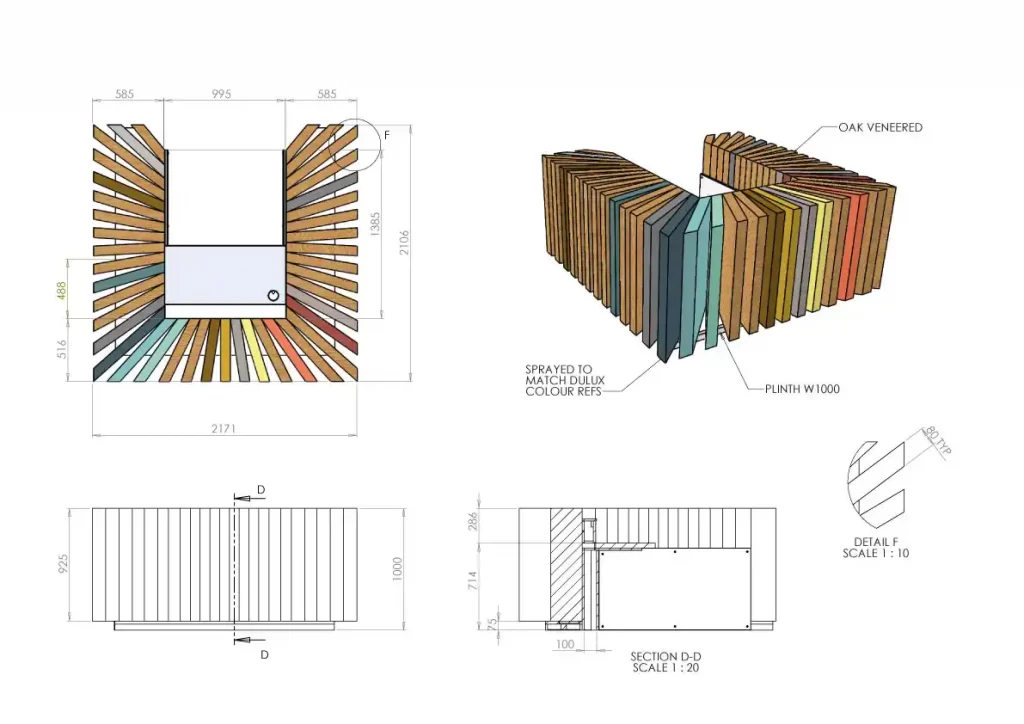

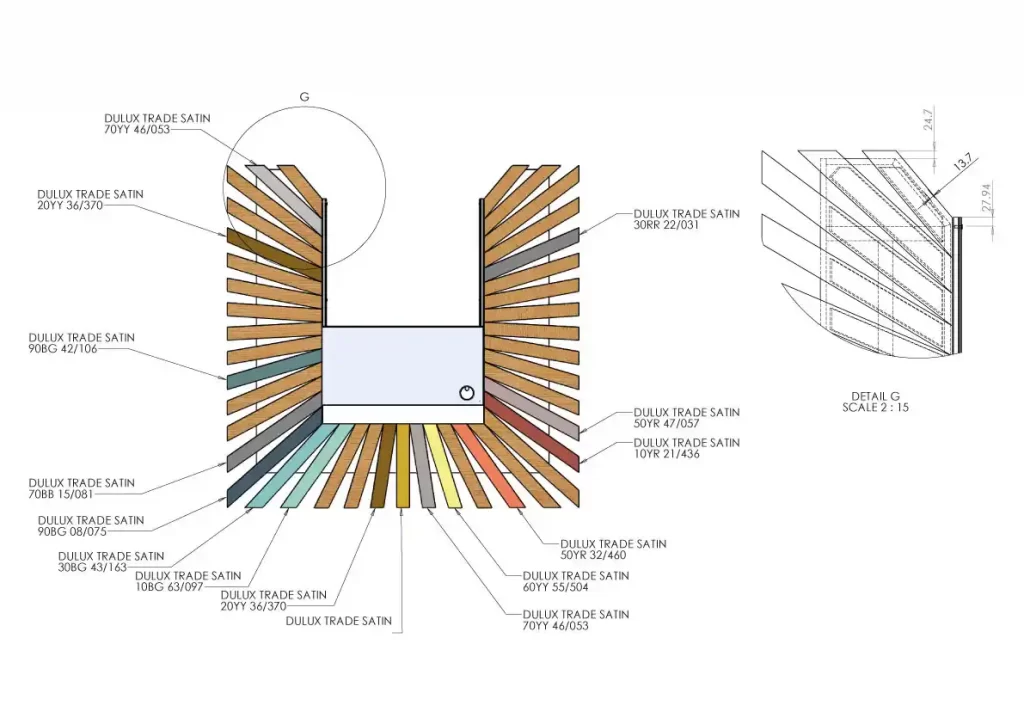

- For the modular cubby walls, we specified moisture-resistant MDF, spray primed and finished with a durable satin top coat.

- The reception desk was built in sections so it could be moved easily. Wear surfaces used laminated MDF.

- Other sections used moisture-resistant MDF, primed and finished in satin. Feature panels were MDF with solid oak veneer.

- Each upstand sits on a metal base for stability.

Before delivery, we trial-built each element in the factory to verify interfaces and tolerances to reassure the team that there would be no issues with installation at AkzoNobel’s head office in Slough. The scope included placement of units, fixing of CNC’d partitions, and setting out of modular cubby walls and sample displays.

The chosen material set supports maintenance: laminate-faced joinery, powder-coated steel and painted feature plinths. Individual plinths and panels are modular and can be replaced without a full strip-out.

The centre operates as an immersive brand environment. Retailers and staff can view colour ranges and new products in context.

Planning a customer centre or workspace fit-out? Send your drawings for a review or book a factory tour.