Ripple needed a bright, branded meeting suite with adjacent focus rooms and spaces for quick collaboration. It had to withstand back-to-back meetings, keep AV tidy and be easy to clean. Success meant durable furniture, clear cable routes and better acoustics, without adding maintenance time.

We led the concept and technical design, then manufactured and installed under one roof for schedule control. We turned the concept into buildable drawing packs and set out all service points for power, data and AV.

- Meeting tables run on ERW mild-steel box frames with CR4 sheet details for strength and durability. Tops are laminated MDF, CNC-machined and edge-banded for impact resistance and easy cleaning.

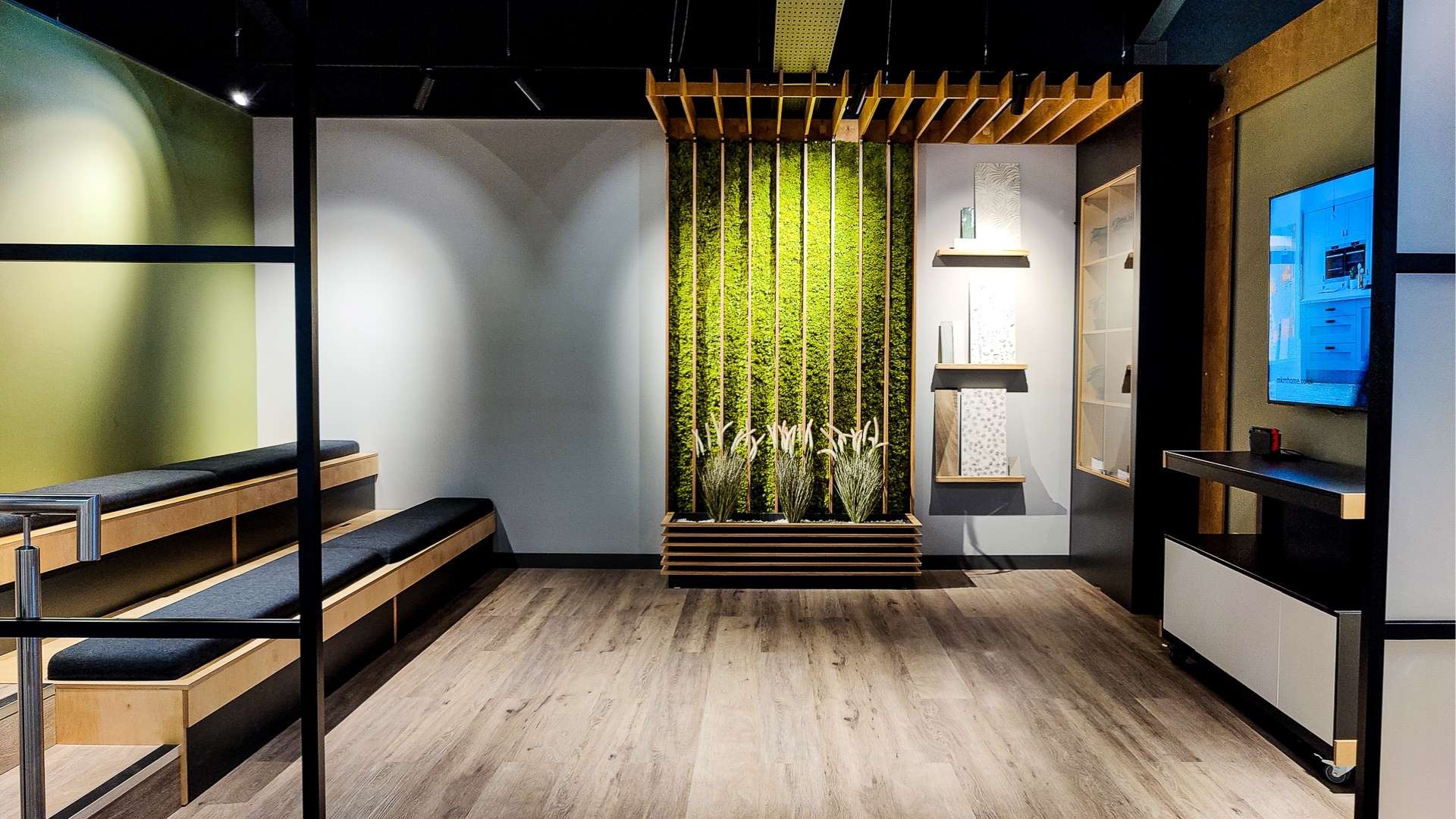

- An MDF acoustic-panel feature wall on a ply substrate cuts reverberation.

- Triangular illuminated inserts sit in laser-cut housings.

- We used water-based paint on the inserts, so it’s easier to touch up without the smell.

- The mix of laminate, steel and ply favours repair over replacement.

- When surfaces mark or fittings date, the part can be swapped without having to update the whole structure, which reduces waste and extends service life.

- Redwood and ply trims protect exposed edges, reduce chipping and keep the finish consistent across rooms

- The focus rooms have glass fronts with integrated thresholds. Screen and floor-box positions are coordinated, so cables stay out of sight.

We labelled components by room and set the sequence from approved drawings. Screens, table feeds and floor boxes align with the final layout, which reduces on-site tweaks. Access, waste and safety followed site packs and RAMS.

We used water-based paint on the inserts, so it’s easier to touch up without the smell. The mix of laminate, steel and ply favours repair over replacement. When surfaces mark or fittings date, the part can be swapped without having to update the whole structure, which reduces waste and extends service life.

Planning a new meeting suite or focus rooms? Get in touch to discuss or book a factory visit.