We translated the concept into buildable technical packs, then manufactured under one roof for schedule control. Components were labelled by room/position to reduce on-site handling.

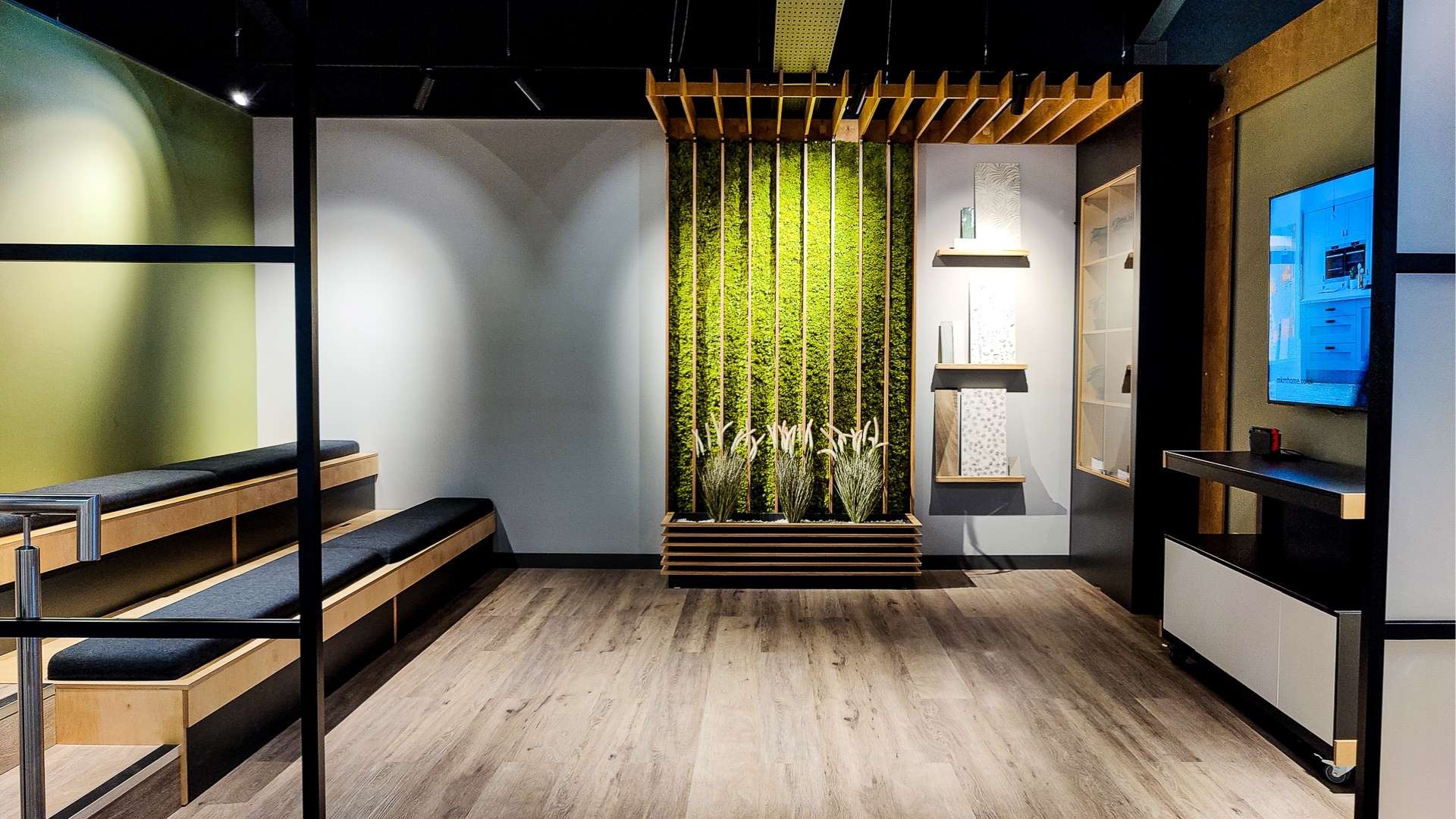

The scheme is built around birch ply, clear lacquered. We used it for carcasses, benches and trims, leaving edges exposed and sealing them for durability and easy cleaning. Selected faces and junction pieces are finished in black satin for contrast. Steel components, including frames, protection angles and brackets, are also finished in black satin for durability and design consistency.

Slatted surrounds define the feature wall, framing an artificial moss insert, adding colour and softening sound without live-plant maintenance.

Tiered auditorium seating is modular and serviceable. Each module has a removable birch ply top, clear lacquered for easy access and wipe-down, with upholstered seat pads that can also be removed. Geometry is simple and robust, so pads align cleanly and surfaces stay tidy. A movable birch-ply table on braked castors supports quick layout changes and parks neatly when floors need to be cleared. The reception counter follows the same material design with a birch-ply carcass with a black satin work surface, concealed cable routes and practical storage so the welcome point feels cohesive with the other spaces.

The scheme favours repair over replacement. Tops, fascias and pads are fixed with construction that makes it easy to swap pieces out. Runners, castors, and power modules can be replaced independently. End-of-life disassembly is simple as timber, boards, steel and upholstery separate at the fixings.

Contact us to discuss manufacturing for your next training space.